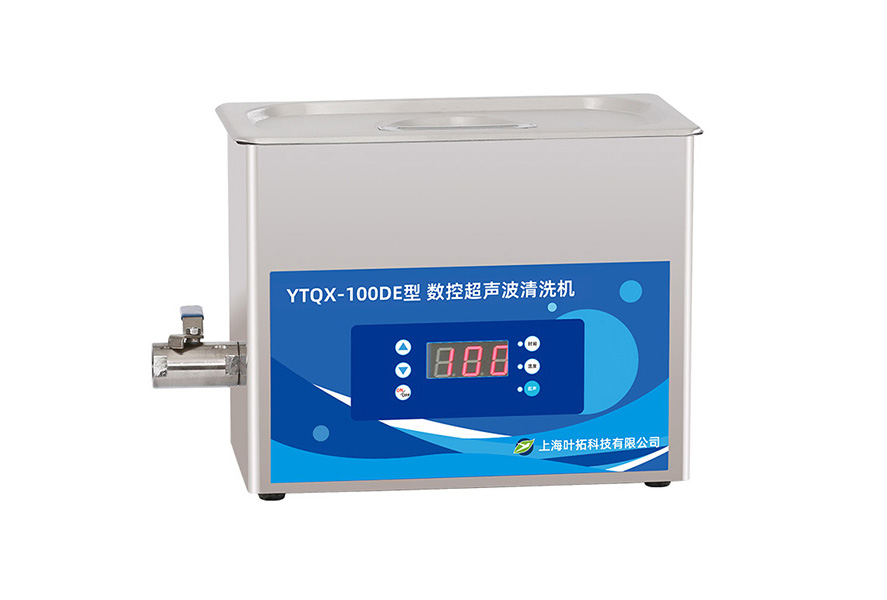

When using a CNC ultrasonic cleaning machine, a series of precautions need to be followed to ensure the normal operation of the equipment, the cleaning effect, and the safety of the operators. The following are the main precautions when using a CNC ultrasonic cleaning machine:

1. Selection of cleaning solution

Suitable cleaning solution: Different workpiece materials and cleaning requirements require the selection of corresponding cleaning solutions. For example, metal parts typically use weakly alkaline or neutral cleaning solutions, while glass or plastic is suitable for using weakly acidic cleaning solutions. The choice of cleaning solution directly affects the cleaning effect.

Replacement of cleaning solution: Cleaning solution should be replaced regularly to avoid long-term use that may result in decreased cleaning effectiveness or secondary pollution. Especially in frequent use, it is even more important to ensure the cleanliness of the cleaning solution.

2. Equipment preheating

Preheating time: If heating is required for cleaning, it is recommended to turn on the heating function first and wait for the cleaning solution to reach the set temperature before starting ultrasonic cleaning. Ensuring that ultrasound operates at the appropriate temperature can improve cleaning efficiency.

3. Placement of cleaning materials

Suspended placement: Do not place the cleaning object directly at the bottom of the ultrasonic cleaning machine slot. Items should be suspended in the cleaning solution using a cleaning basket or bracket to avoid damage to the ultrasonic vibration head due to contact with heavy objects, and to ensure that the cavitation effect of the cleaning solution can be fully utilized.

The spacing between items: Items should not be stacked on top of each other or placed too tightly to avoid affecting the propagation of ultrasonic waves, ensuring that the surface of each object is uniformly stressed and achieving the cleaning effect.

4. All operators are present

Wear gloves and protective goggles: When using an ultrasonic cleaning machine, especially when dealing with chemical cleaning solutions such as strong acids and alkalis, operators should wear gloves and protective goggles to avoid damage to the skin and eyes caused by the cleaning solution.

Avoid physical contact with cleaning solution: During ultrasonic cleaning, operators should avoid direct contact with the cleaning solution with their hands or other body parts, as the cavitation effect generated by ultrasonic waves in the cleaning solution may cause minor harm to the human body.

5. Prevent dry running

Avoid liquid free idling: Ultrasonic cleaning machines are strictly prohibited from operating without cleaning solution, as this may cause damage to the ultrasonic transducer and shorten the service life of the equipment. Ensure that the liquid level of the cleaning solution reaches a height, usually covering more than one-third of the transducer.

6. Control of cleaning time

Appropriate cleaning time: Ultrasonic cleaning is not necessarily better with longer cleaning time. The usual cleaning time ranges from 3 to 10 minutes, and prolonged cleaning may cause corrosion or damage to the surface of the workpiece. The cleaning time should be reasonably set according to factors such as workpiece material and dirt type.

7. Equipment maintenance and upkeep

Regular cleaning: After cleaning is completed, promptly drain the liquid from the cleaning tank, dry the cleaning tank, and clean any residue. Regularly inspect and clean the interior of the tank to avoid the accumulation of dirt, debris, or corrosive substances.

Vibration head maintenance: Regularly inspect the ultrasonic vibration head (transducer) for looseness, wear, or abnormal noise. The vibration head is the core component of the equipment, and any problems should be repaired or replaced in a timely manner.

Electrical component maintenance: Regularly check the status of electrical components such as power cords and control panels to ensure that electrical connections are stable and not loose, and to avoid potential hazards such as short circuits.

8. Selection of Ultrasonic Frequency

Appropriate frequency: Choose the appropriate ultrasonic frequency according to different cleaning objects. In general, lower frequencies (20-40kHz) are suitable for cleaning rough surfaces or removing larger particles of dirt, while higher frequencies (60-80kHz) are suitable for cleaning precision components to avoid damaging the surface of the workpiece.

9. Treatment after cleaning

Drying of workpieces: After cleaning, the workpieces should be promptly removed and suitable drying methods should be selected according to different materials and uses, such as natural air drying, hot air drying, or alcohol washing, to prevent water stains or secondary pollution on the surface of the workpieces.

Post treatment: For workpieces that still require surface treatment after cleaning, such as coating, spraying, etc., ensure that the workpiece is cleaned and dried before proceeding to the next step of the process to avoid surface residue affecting the subsequent treatment effect.

10. Appropriate power supply

Stable power supply: Ensure that the device uses a stable power supply voltage to prevent voltage fluctuations from affecting the device's operational performance or causing malfunctions. Especially in industrial use scenarios, appropriate power sources and sockets should be configured according to the power requirements of the equipment.

summary

CNC ultrasonic cleaning machines are widely used in multiple industries due to their cleaning capabilities. However, during use, attention should be paid to the selection of cleaning solution, operation, equipment maintenance, and control of cleaning time and frequency to ensure the normal operation and cleaning effect of the equipment, while extending the service life of the equipment and ensuring the safety of the operators.

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore